1. Light Emitting Diodes

Light Emitting Diodes (LEDs) have become the dominant technology for illumination across residential, automotive, and motorcycle applications.

Their advantages include high luminous efficiency, compact design, low power consumption, and long operational lifespan.

This report presents a technical overview of LED systems, focusing on design architecture, performance parameters, and engineering challenges in three sectors:

- Residential Lighting (AC grid systems)

- Automotive Lighting (12–24 V DC systems)

- Motorcycle Lighting (compact, vibration-prone DC systems)

2. FUNDAMENTALS OF LED TECHNOLOGY

2.1 Electrical and Optical Parameters

| Parameter | Description | Typical Value |

|---|---|---|

| Forward Voltage (Vf) | Voltage drop during conduction | 2–3.6 V |

| Forward Current (If) | Nominal operating current | 10–1000 mA |

| Efficiency | Luminous efficacy | 100–220 lm/W |

| Color Temperature | Correlated color temperature (CCT) | 2700K–6500K |

| Lifetime (L70) | Time until brightness drops to 70% | 25,000–100,000 h |

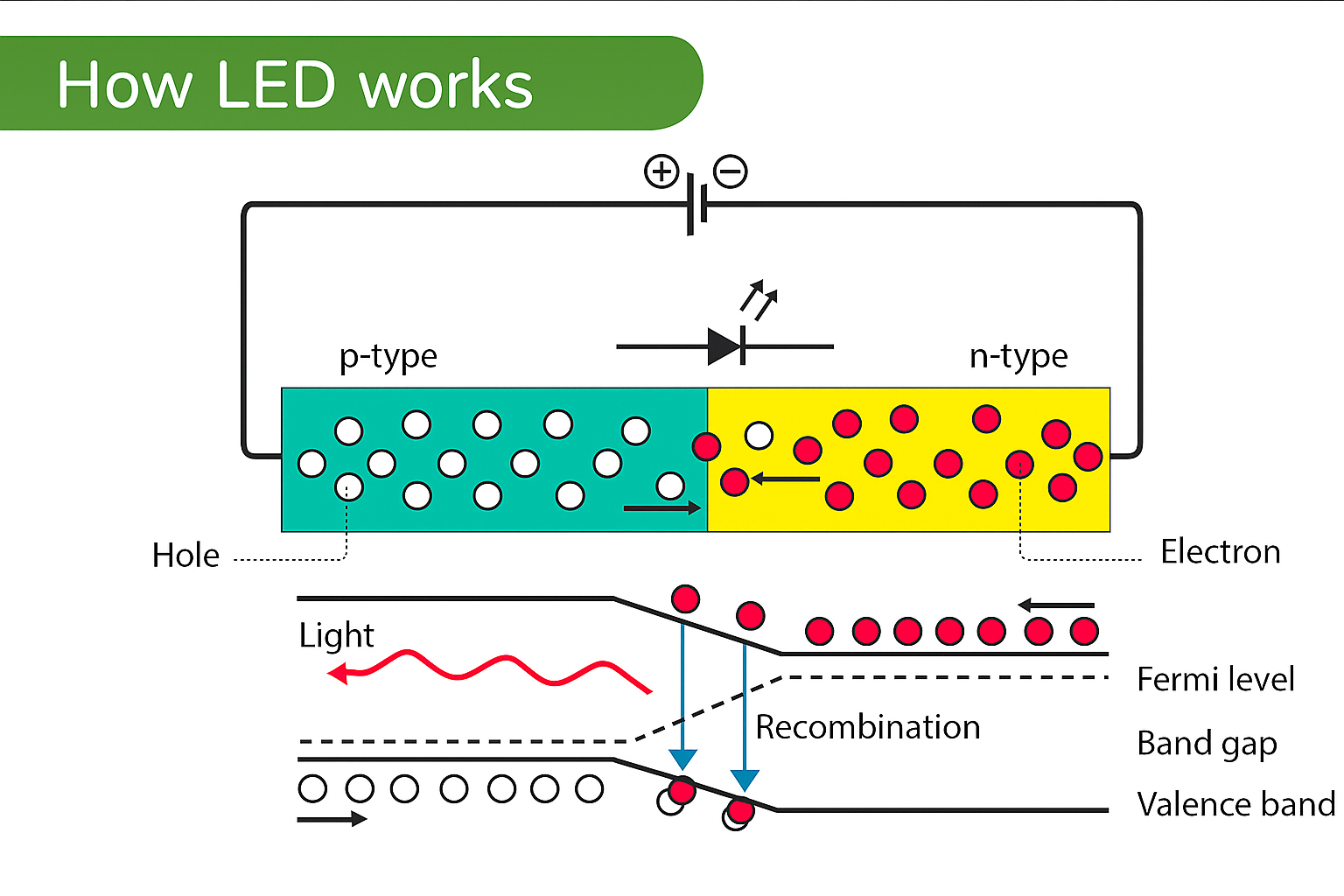

LEDs operate through electroluminescence, where semiconductor materials emit photons as current passes through the p–n junction.

The emitted wavelength (color) depends on semiconductor composition and phosphor coating.

Reference: ScienceDirect – LEDs for Lighting: Physics and Prospects

3. LED LIGHTING IN RESIDENTIAL BUILDINGS

3.1 Electrical Design

- Operates on 220–240 V AC converted to DC via constant-current drivers.

- Drivers maintain constant output despite voltage fluctuations.

- Power Factor Correction (PFC) circuits improve efficiency and reduce harmonic distortion.

3.2 Thermal Management

- Junction temperatures must stay below 85 °C.

- Common techniques:

- Aluminum heat sinks

- Thermal interface pads

- Ventilated lamp housings

3.3 Color and Control Systems

- CRI > 90 recommended for indoor use.

- CCT:

- 2700K (warm) – living areas

- 4000K (neutral) – kitchens

- 6500K (cool) – offices

- Smart Controls: Wi-Fi, Zigbee, or BLE for dimming and scheduling.

3.4 Comparative Efficiency

| Type | Power (W) | Lumens | Efficiency (lm/W) |

|---|---|---|---|

| Incandescent | 60 | 800 | 13 |

| CFL | 15 | 800 | 53 |

| LED | 9 | 800 | 89 |

Reference: Lumimuse – Understanding LED Technology

Illustration:

4. LED LIGHTING IN AUTOMOTIVE SYSTEMS

4.1 System Overview

Automotive lighting employs LED modules integrated with driver circuits and vehicle control systems.

Typical sub-systems include:

- Headlamps / DRLs / Taillamps

- Turn signals and interior lamps

- Adaptive Beam Control Systems (linked to vehicle ECU via CAN Bus)

4.2 Electrical Architecture

| Parameter | Value / Range | Notes |

|---|---|---|

| Voltage | 9–16 V DC | Passenger vehicles |

| Current Regulation | 350–1500 mA | Constant-current driver |

| Dimming | PWM (200–1000 Hz) | Brightness modulation |

| Polarity Protection | TVS Diode or Schottky | Prevents reverse connection |

| Cooling | Aluminum PCB + Fan | Maintains < 120 °C junction temp |

4.3 Headlight Module Example

| Component | Specification |

|---|---|

| LED Type | Cree XHP50 / Osram OSLON |

| Power | 20–30 W |

| Output Flux | 3000–4000 lm |

| Optics | Projector lens with cutoff |

| Control | CAN-bus or analog dimming |

4.4 Design Considerations

- Thermal Control: Passive or active cooling.

- EMI Filtering: Inductive filters on driver input/output.

- Optical Tuning: Beam pattern compliance with UNECE R112.

Reference: EE Power – Addressing Automotive LED Design Challenges

Illustration: Car LED H7 Module

5. LED LIGHTING IN MOTORBIKES

5.1 Environmental Constraints

Motorcycles impose additional requirements due to:

- High vibration and shock loads

- Limited space for cooling

- Alternator-based power with unstable DC output

5.2 Electrical Configuration

Motorbike LED circuits typically include:

- Bridge Rectifier → Converts AC to DC

- DC–DC Buck Converter → Regulates LED current

- TVS Protection → Absorbs voltage spikes

5.3 Example Application

| Application | Voltage | Current | Power | Notes |

|---|---|---|---|---|

| Headlamp | 12 V | 1.5 A | 18 W | Dual-beam LED array |

| Turn Signal | 12 V | 0.2 A | 2.4 W | Sequential amber pattern |

| Brake Light | 12 V | 0.3 A | 3.6 W | High-visibility red LED |

5.4 Reliability Considerations

- Conformal coating for PCB protection.

- IP67 sealing for water ingress prevention.

- Anti-vibration mounting brackets.

Reference: EagleLights – Motorcycle LED Lighting Guide

Illustration: Motorbike H4 LED

6. ENGINEERING CHALLENGES

| Challenge | Description | Mitigation |

|---|---|---|

| Thermal Dissipation | LED junction heating affects lifetime | Aluminum PCB, thermal vias, heatsinks |

| EMI / EMC Compliance | Driver circuits produce noise | LC filters, shielding, proper layout |

| Voltage Instability | Automotive electrical surges | TVS diodes, buck–boost converters |

| Environmental Sealing | Moisture ingress and corrosion | IP-rated enclosures, silicone potting |

7. FUTURE TRENDS

| Technology | Application | Expected Benefit |

|---|---|---|

| Laser-LED Hybrids | Automotive | > 600 m beam distance |

| Adaptive Smart Beams | Cars & Motorbikes | Real-time beam shaping |

| GaN Drivers | All sectors | Higher switching efficiency |

| Flexible / Micro-LEDs | Interior / Decorative | Lightweight, customizable forms |

Reference: EngineeringMix – Future of Automotive Lighting

8. SUMMARY

| Sector | Supply Type | Control Method | Key Focus |

|---|---|---|---|

| Residential | AC–DC Drivers | Smart IoT / Dimming | Energy Efficiency |

| Automotive | 12–24 V DC | PWM / ECU Control | Safety & Regulation |

| Motorcycle | Rectified DC | Constant-Current Driver | Durability / Compact Design |

9. REFERENCES

- LEDs for Lighting: Basic Physics and Prospects for Energy Savings — ScienceDirect

- Understanding LED Technology in Home Lighting — Lumimuse

- Addressing Automotive LED Design Challenges — EE Power

- A Guide to Motorcycle LED Lights — EagleLights

- Future Automotive Lighting with LED & OLED — EngineeringMix

Author’s note:

- I used LED bulbs on my bike headlights and taillight for more than 3 years. No issue, except on my harley I ocasionally get a red warning for voltage different between led and halogen.

- Used LED bulbs at home for more than 5 years. Recently bought inexpensive 15W Led bulbs (Eilon) from Global store, Thailand. Inexpensive and Good.